Krupp Machinery Shines at CHINAPLAS 2025 with Innovative All-Electric Blow Molding Machine

Times:2025-04-21

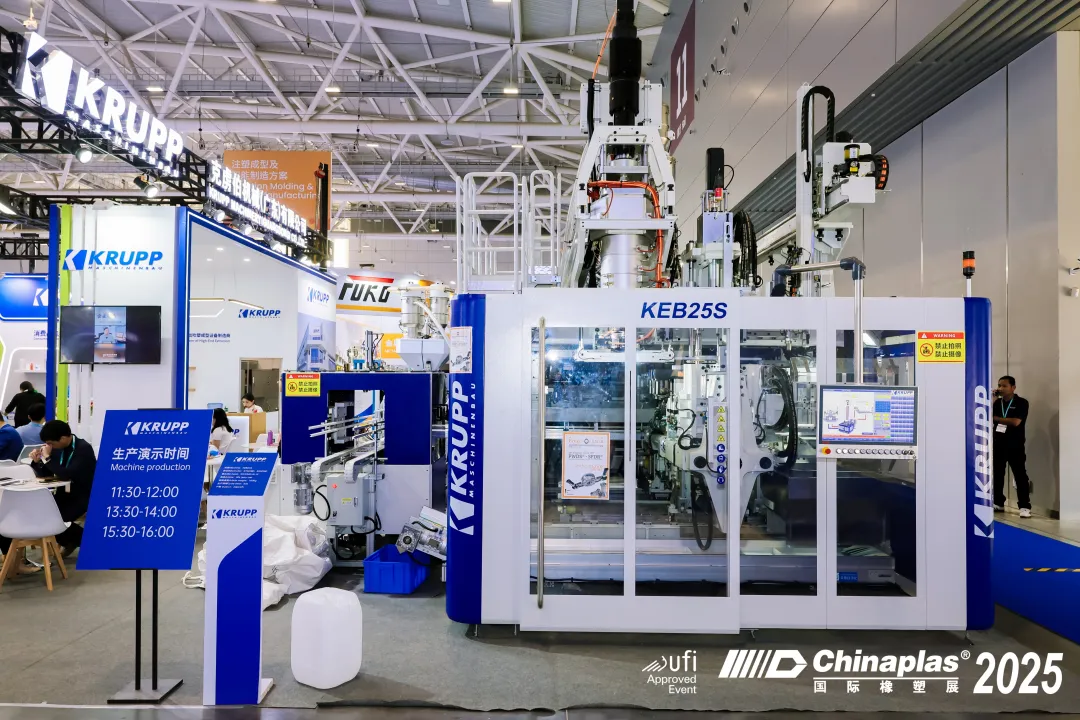

The CHINAPLAS 2025 International Rubber and Plastics Exhibition concluded successfully at the Shenzhen World Exhibition & Convention Center. Krupp Machinery made a remarkable appearance with the global debut of its all-electric extrusion blow molding machine, the KEB25S. With its high efficiency, energy-saving features, and intelligent performance, the machine attracted numerous domestic and international professionals, making it one of the highlights of the event.

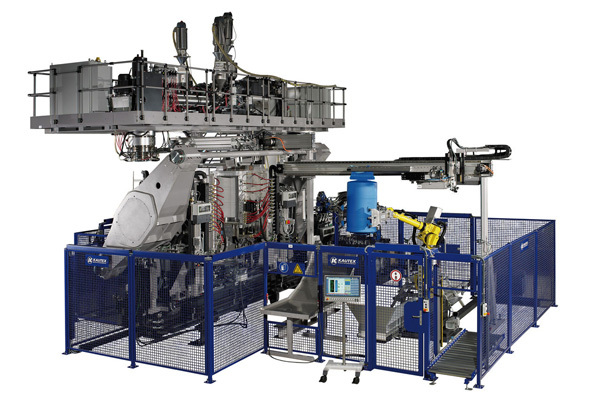

KEB25S: A Breakthrough in Blow Molding Technology

As the centerpiece of Krupp’s exhibition, the KEB25S addresses key industry challenges with several core advantages:

Energy Efficiency Revolution:

The toggle clamping unit is driven by a high-performance servo motor and an intelligent energy recovery system that converts braking energy into electricity, feeding it back to the grid. This innovation boosts power efficiency by over 40% while ensuring fast and stable mold clamping with optimized energy consumption.

Precision Control:

Equipped with an advanced closed-loop control system, the KEB25S achieves high-precision positioning and smooth speed regulation during high-speed production, ensuring cycle-to-cycle consistency and significantly improving product quality.

Eco-Friendly Operation:

The hydraulic-free design eliminates oil leakage risks, making it ideal for industries with strict hygiene requirements, such as food packaging and pharmaceutical containers.

Simplified Maintenance:

By replacing traditional hydraulic systems with an all-electric design, the KEB25S removes complex oil pipelines, reducing maintenance costs by over 60%. Routine checks on the electrical system are now sufficient for upkeep.

Smart Integration:

The machine supports digital control (PLC, IoT technology), enabling real-time monitoring, smart diagnostics, and production data tracing. Customers can access operational parameters, energy consumption data, and production reports anytime, aligning perfectly with Industry 4.0 smart manufacturing demands.

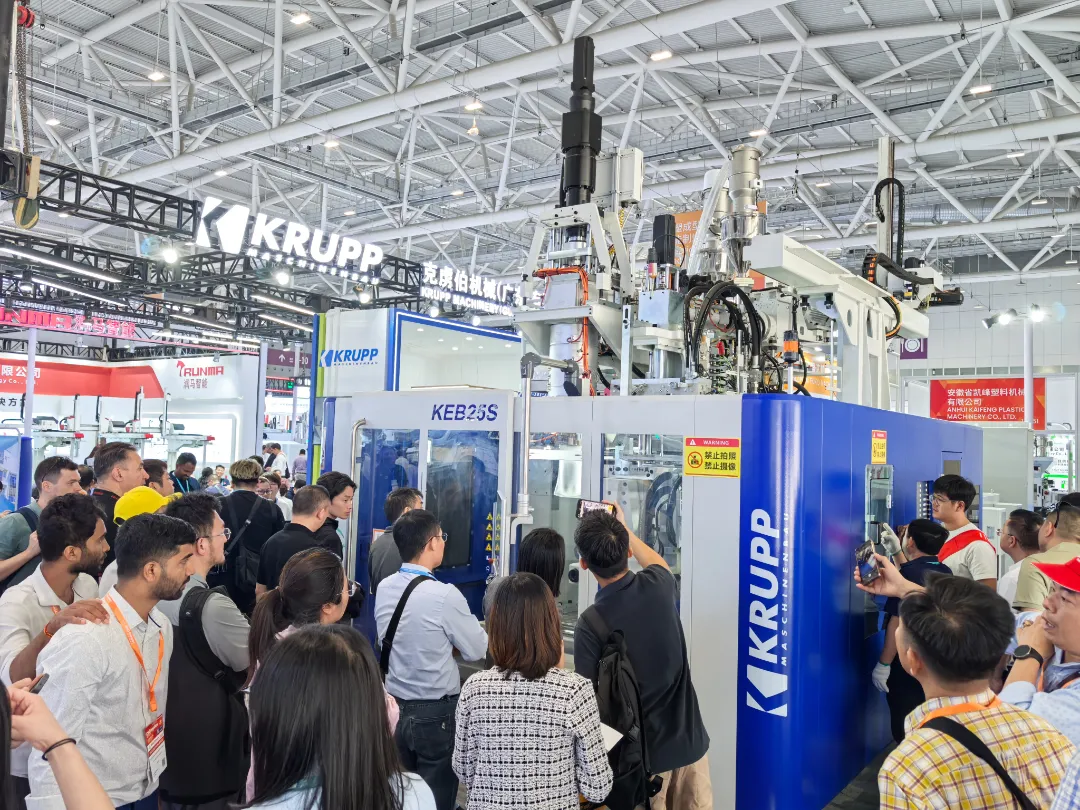

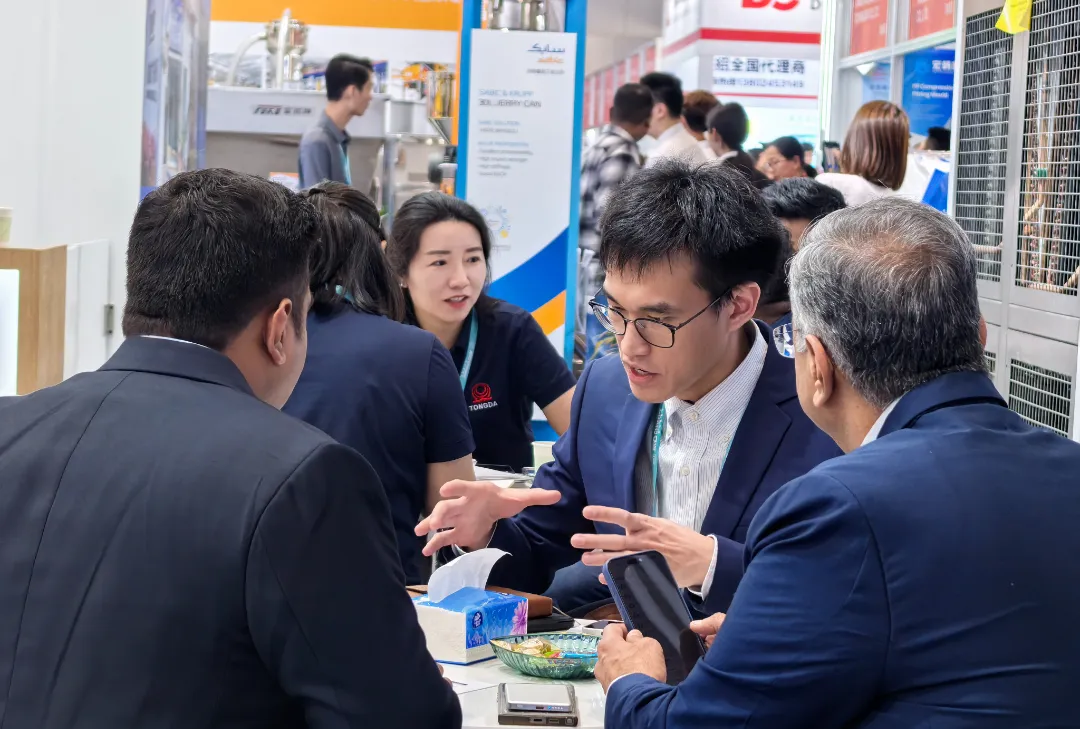

Strong Interest from Global Clients with Active Negotiations

During the exhibition, Krupp’s booth was constantly crowded, drawing a continuous stream of visitors—a true "sea of people" scene. Overseas clients from Europe, Southeast Asia, the Middle East, and beyond stopped by for in-depth discussions. The live demonstration of the KEB25S producing 30L industrial stacking drums attracted large crowds, with Krupp’s technical team providing detailed explanations on machine performance, material compatibility, and after-sales services. Several clients, after thoroughly understanding the KEB25S’s technical advantages, expressed preliminary purchasing intentions.

|  |

|  |

|  |

|  |

A representative from a Southeast Asian packaging company commented:

"The machine’s stability and product quality are impressive. We are currently evaluating the possibility of introducing it into our production line."

A Chinese packaging client added:

"We’ve been searching for a more eco-friendly and efficient blow molding solution, and Krupp’s machine perfectly meets our needs—especially its all-electric design, which helps us comply with increasingly stringent environmental regulations."

|  |

|  |

|  |

|  |

Driving Innovation for a Sustainable Future

As global manufacturing shifts toward intelligent and green production, Krupp Machinery continues to invest in R&D to advance blow molding technology. The KEB25S is not just a new product—it represents the future of efficient and sustainable manufacturing.

"Customer feedback reinforces our commitment to innovation," said Gui Jinyu, Deputy General Manager of Krupp Machinery. "We will accelerate market promotion to help more companies experience the value of our all-electric blow molding technology."

Though the exhibition has ended, Krupp’s pursuit of innovation continues. By leveraging its technological strengths, the company remains dedicated to driving green transformation in the industry, partnering with global clients to usher in a new era of smart, efficient, and sustainable manufacturing.

Other Information