KEB series - setting new standards in efficient blow molding production

Classification:

KEB

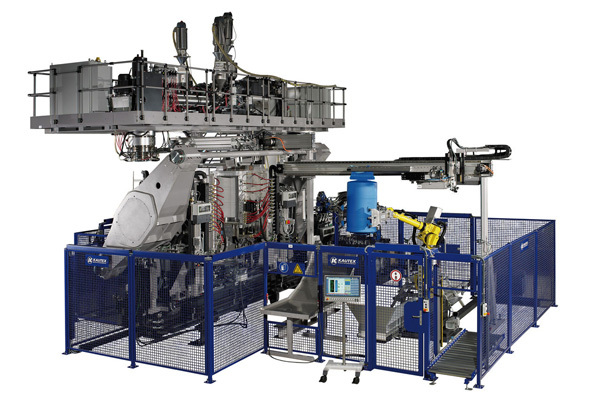

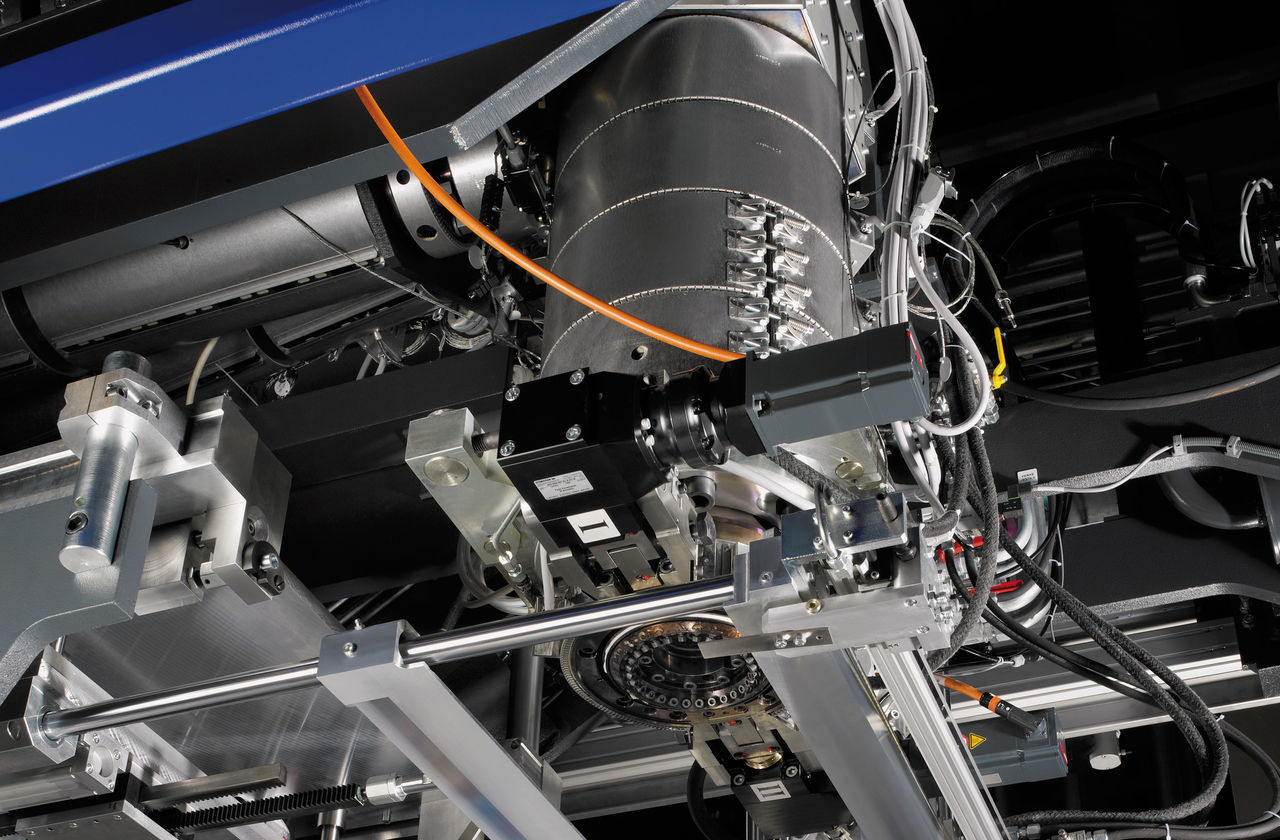

KEB blow molding machines have set a new benchmark in the field of plastic bottle and jerry can production with top performance and extremely low energy costs. The KEB series covers single and double stations, with strong clamping force, capable of producing a variety of bottles and jerry cans. Equipped with advanced multi-layer co-extrusion technology, it reduces masterbatch consumption and improves environmental benefits by recycling. Many models have passed the Euromap 46.1 energy efficiency standard test and have excellent energy efficiency. The machine can be equipped with an IntelliGate module to integrate post-processing such as flash cutting, post-cooling, weighing, and leak detection to further increase efficiency and meet personalized production needs. KEB blow molding machine is your ideal choice for ultra-efficient and intelligent production.

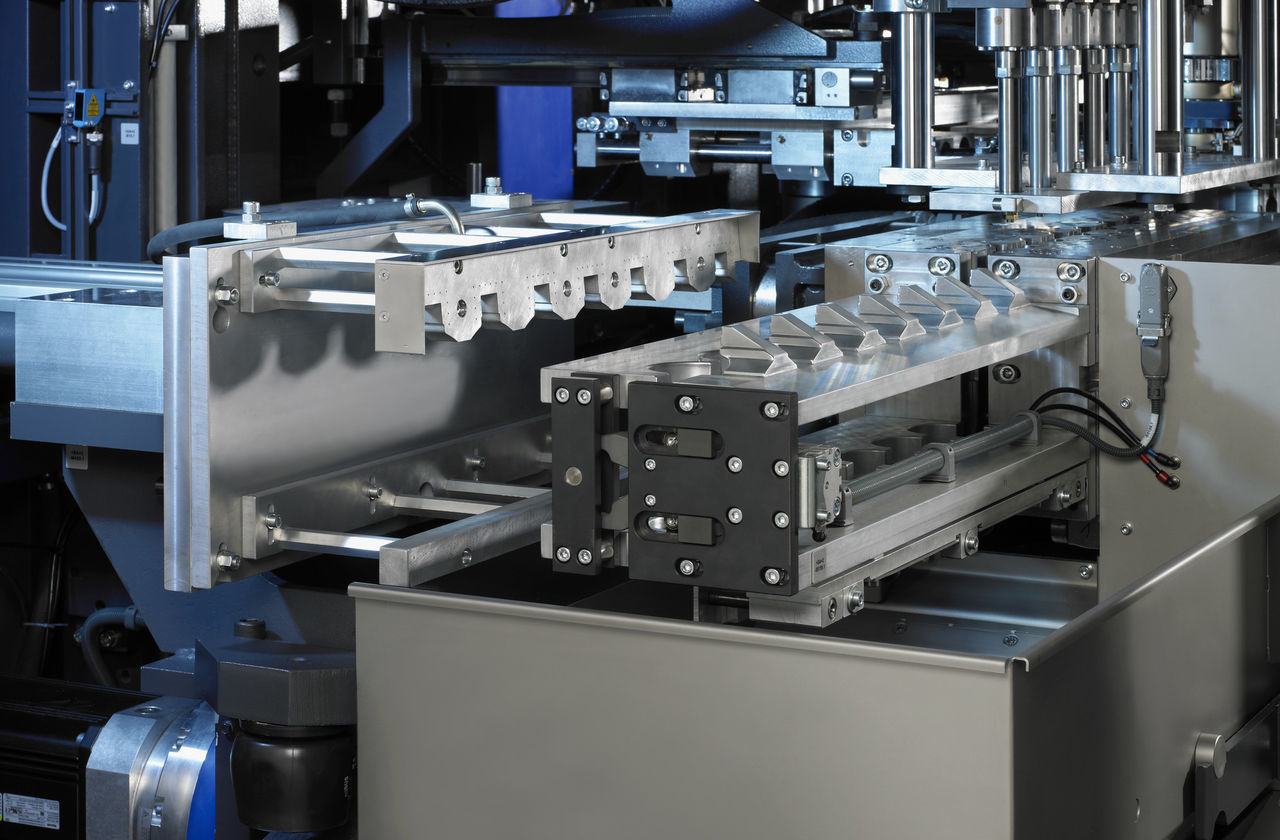

■ Ultra-short cycle time and mold change time

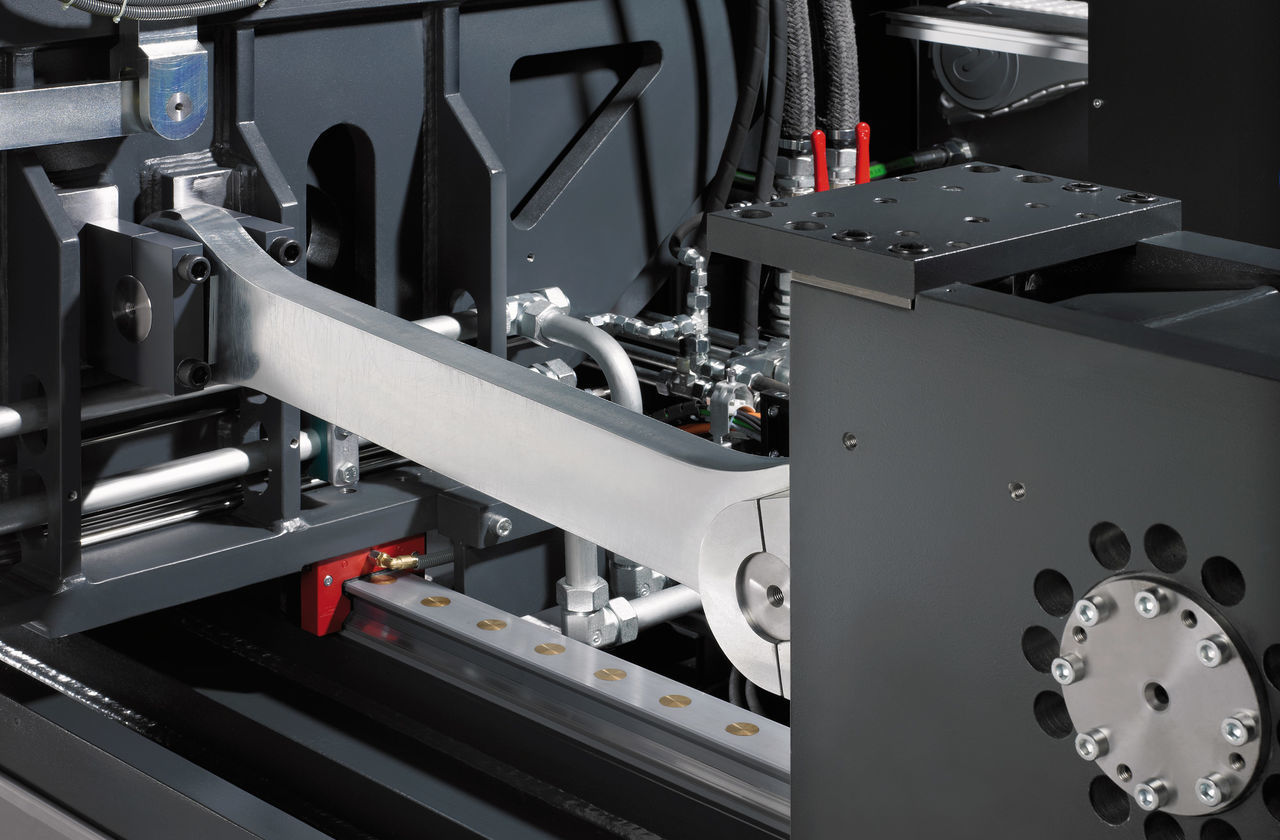

■ Durable crank drive with long service life

■ Quick change system for fast product changeovers

■ Modular design, optimized space utilization, simple modification

Key words:

KEB series - setting new standards in efficient blow molding production

undefined

Technical Data

| KEB series | KEB40 | KEB60 | KEB80 | KEB400 |

| Shuttle stroke (mm) | 620 | 770 | 970 | 670 |

| Clamp stroke (max. mm) | 250 | 250 | 250 | 400 |

| Blowpin stroke (max. mm) | 180 | 180 | 180 | 250 |

| Clamping froce (kN) | 250 | 300 | 400 | 300 |

| Calibration force (kN) | 35 | 40 | 55 | 35 |

| Dry cycle time (s) | 2.1 | 2.3 | 2.6 | 4.8 |

| Mold | ||||

| Width (max. mm) | 610 | 760 | 960 | 660 |

| Length (max. mm) | 380 | 380 | 380 | 700 |

| Thickness (min. mm) | 2×150 | 2×150 | 2×150 | 2×250 |

| Weight (max. kg) | 2×200 | 2×225 | 2×300 | 2×600 |

KRUPP Machinery, your ideal business partner

Comprehensive Adaptation

Flexible combination of extruder and die head for various packaging applications

Space Saving

Compact structure, optimized space utilization

Efficient Production

High-speed operation, smooth and stable movement, high repetition accuracy

Economic Benefits

Extremely low energy consumption, ultra-short cycle time

Sustainability

Save materials and energy to enable PCR material processing

Local display of machine

Here is the placeholder text

Here is the placeholder text

Here is the placeholder text

Here is the placeholder text

Other Products

KCC series - consistently focused on cost efficiency

KEB series - setting new standards in efficient blow molding production

KSH series - compact and efficient production for drums

KBS series - the all-rounder to perfectly fit your needs

Product Inquiry

* Note: Please fill in the information accurately and keep your mobile available. We will contact you as soon as possible.

Krupp Machinery (Guangdong) Co., Ltd.

Sales: 0757-27330931

After sales: 0757-27330936 / 27330957

Spare part: 0757-27330939

Address: Fu’An Industrial District · Shunde · Foshan · Guangdong · PRC ·

Post Code: 528322

Krupp Machinery

Official WeChat

You can also submit your information online and we will respond to you within 24 hours!